Rubber Expansion Joints / Bellows

Rubber Expansion Joints

Overview

Rubber expansion joints are flexible connectors made from natural or synthetic elastomers and fabrics, designed to absorb movement in piping systems. They are used to accommodate thermal expansion, vibration, and other mechanical forces that can cause stress on pipes and equipment. Our high-quality rubber expansion joints are engineered to provide flexibility and resilience, making them the ideal choice for a wide range of applications. Whether you are dealing with thermal expansion, mechanical stress, or vibration, our products ensure your systems run smoothly and efficiently.

Design and Material

Our rubber expansion joints are crafted from natural and synthetic elastomers, including EPDM, Nitrile and Hypalon. These materials, combined with robust reinforcements, create a product that excels in both strength and durability. Our joints are available in various designs, from single arch for minimal movement absorption to multiple arch configurations for greater flexibility. Tied rubber bellows are also available, these are designed to accommodate misalignment and both axial and lateral movement. Whatever your requirements, Flexmetallic Industries can offer the perfect solution

Adapting to Dynamic Environments

One of the primary functions of rubber bellows is to accommodate the thermal expansion and contraction of pipelines resulting from temperature variations. As temperatures fluctuate, pipelines expand and contract, exerting tremendous forces that can lead to structural damage if not properly managed. rubber bellows act as flexible joints, absorbing these movements and preventing undue stress on the system.

Moreover, they excel in dampening vibrations generated by machinery, pumps, or turbulent fluid flow within pipelines. By absorbing and dissipating vibrations, bellows mitigate the risk of equipment damage and ensure smoother operation of industrial processes.

The versatility of rubber bellows extends across various industrial sectors, where they find application in an array of critical systems:

Versatility Across Industries

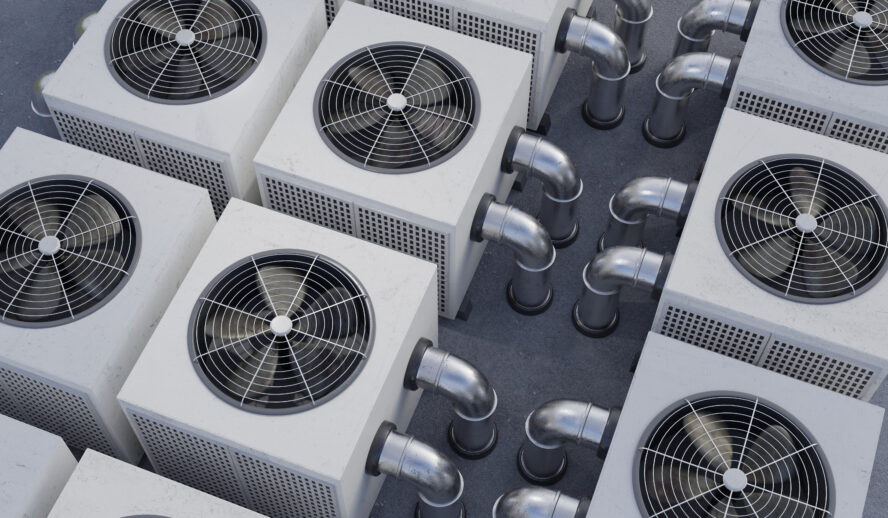

HVAC Systems

Ensure optimal performance in heating, ventilation, and air conditioning by managing thermal expansion and vibration.

Water and Wastewater Treatment

Our joints are perfect for handling pressure and flow variations while resisting corrosion from harsh chemicals

Power Plants

Ideal for cooling systems and steam lines, expansion joints withstand temperature variations and vibration.

Marine Applications

Expansion joints provide reliability and flexibility in ships and offshore platforms, dealing with constant motion and environmental changes.

Industrial Piping

From chemical plants to refineries, expansion joints manage thermal expansion and reduce vibration effectively.

Pumping

In pumps and rotating equipment, rubber bellows serve as sealing elements, preventing leakage of fluids or gases while allowing axial movement to compensate for shaft misalignment or thermal expansion.

Choosing Flexmetallic means selecting products that offer

Exceptional Flexibility

Our joints provide significant movement absorption, ensuring smooth operation

Superior Vibration Damping

Protect your equipment with our advanced vibration reduction capabilities

Outstanding Chemical Resistance:

Our materials are designed to withstand harsh chemicals and environmental conditions

Easy Installation and Maintenance

Save time and reduce costs with our user-friendly designs

Tailored Solutions for Your Needs

At Flexmetallic Industries, we understand that each application is unique. Our team of experts is dedicated to helping you find the perfect rubber expansion joints for your specific requirements. We consider factors such as temperature range, pressure rating, chemical compatibility, and movement requirements to deliver a solution that fits seamlessly into your system.

Contact us today to learn more about our products and how we can support your business with our exceptional solutions.

Industries

Get in touch

It’s time we talked, send a message

Speak to an experienced engineer to discuss your unique requirements