Engineering & Building Industry

In the realm of engineering, innovation is the cornerstone of progress. Among the many tools and materials utilised in construction and infrastructure development, metal hoses stand out as a versatile solution for various challenges encountered in the building industry.

Flex Metallic

Metal Hose Engineering

In the realm of engineering, innovation is the cornerstone of progress. Among the many tools and materials utilized in construction and infrastructure development, metal hoses stand out as a versatile solution for various challenges encountered in the building industry.

Increasing industrial development within the economy places much higher demand on machinery and electrical equipment highlighting the importance on quality, reliability, versatility and longevity on both systems and components.

With demand for higher quality products increasing, functionally reliable hose connections with long life spans are required. Fully Stainless steel Flexmetallic hoses provide the best solution for it.

These flexible conduits, often overlooked, play a crucial role in ensuring the efficiency, safety, and longevity of structures.

Flexible Conduit Systems

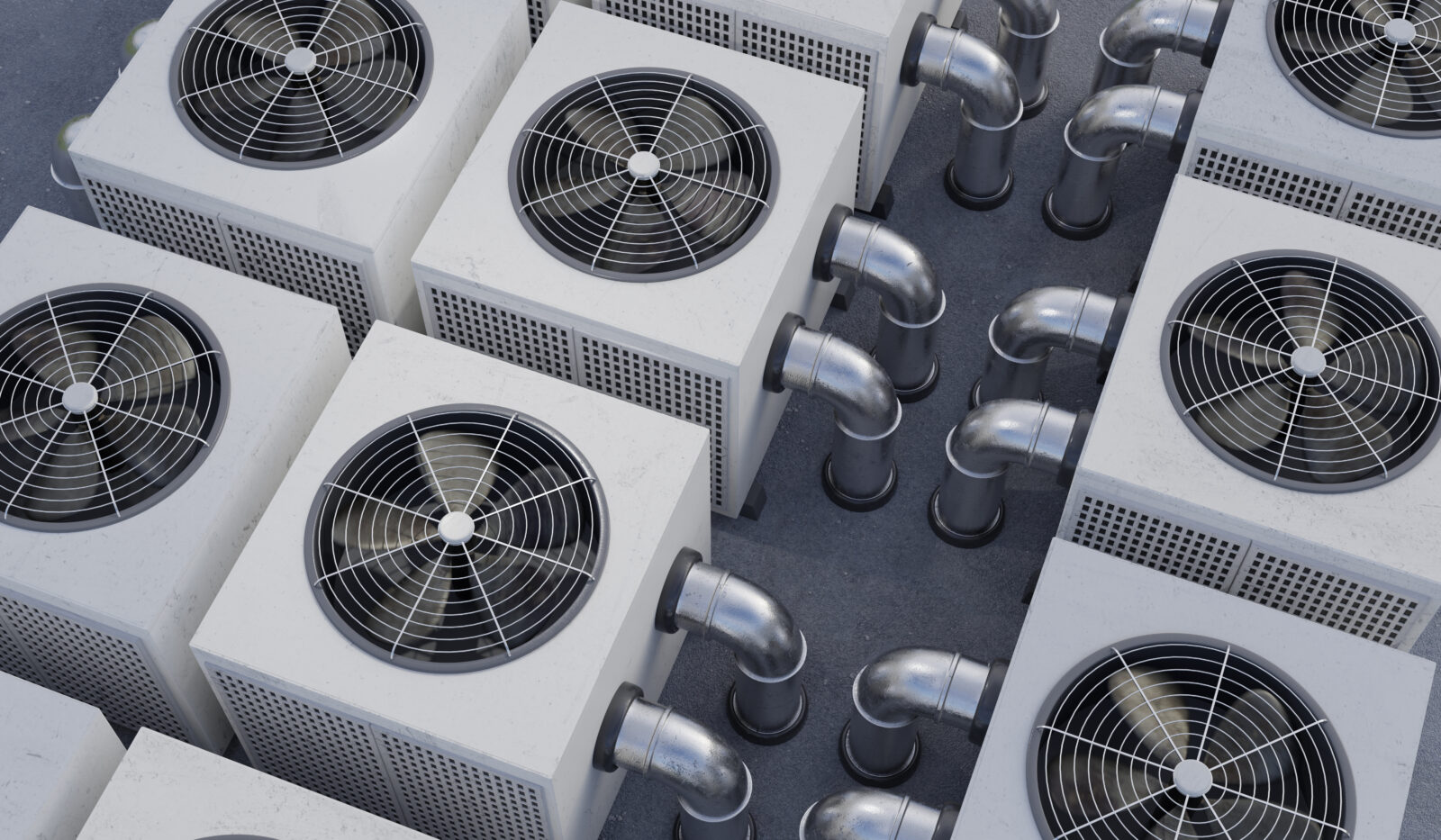

One of the primary functions of metal hoses in building engineering is serving as flexible conduit systems. These hoses allow for the safe and efficient passage of fluids, gases, and are sometimes used to pass electrical wires through challenging spaces within structures. Whether it's routing plumbing lines or accommodating HVAC ducts in complex architectural designs, metal hoses offer unparalleled adaptability.

Thermal Expansion and Contraction

In a dynamic environment where temperatures fluctuate, thermal expansion and contraction can pose significant challenges to building materials. Metal hoses, with their inherent flexibility and resilience, provide an effective solution. By absorbing the expansion and contraction forces caused by temperature variations, these hoses help prevent structural damage and ensure the integrity of building systems over time.

Vibration Dampening

Mechanical equipment, such as pumps, compressors, and HVAC systems, often generate vibrations during operation. Left unchecked, these vibrations can lead to equipment malfunction and structural issues within buildings. Metal hoses act as effective vibration dampeners, absorbing and dissipating kinetic energy to minimize the transmission of vibrations to surrounding structures. This not only protects building components but also aids in reducing noise levels.

Corrosion Resistance

In harsh environments where exposure to moisture, chemicals, and corrosive substances is common, traditional piping materials may deteriorate rapidly, compromising structural integrity and safety. Stainless steel hoses, constructed from corrosion-resistant materials, offer superior durability and longevity in such conditions. Their robust construction ensures reliable performance even in the most demanding applications, making them indispensable in corrosive environments within buildings.

Seismic and Movement Joints

In regions prone to seismic activity or where buildings are subjected to significant movement due to factors like settlement or expansion, the use of metal hoses becomes imperative. These hoses are employed to create flexible joints that accommodate structural movement without compromising the integrity of building systems. By allowing controlled movement, metal hoses help mitigate the risk of structural damage during seismic events and ensure the longevity of building infrastructure.

Conclusion

In the intricate tapestry of building engineering, metal hoses emerge as indispensable components contributing to the efficiency, safety, and resilience of structures. From facilitating fluid and gas transfer to mitigating the effects of thermal expansion and seismic activity, their versatility is exceptional.

Flex Metallic

Other Industries

Get in touch

It’s time we talked, send a message

Speak to an experienced engineer to discuss your unique requirements