Metallic Expansion Joints / Bellows

Metallic Expansion Joints

Overview

In the intricate network of industrial pipelines, where temperature, pressure, vibration, and other dynamic forces are in constant flux, the need for reliable and adaptable components is paramount. This is where our metallic bellows or expansion joints are vital components. Accommodating thermal expansion and contraction, absorbing vibrations, correcting misalignments, and mitigating various movements within pipelines. These ingeniously designed components are indispensable across a multitude of industries.

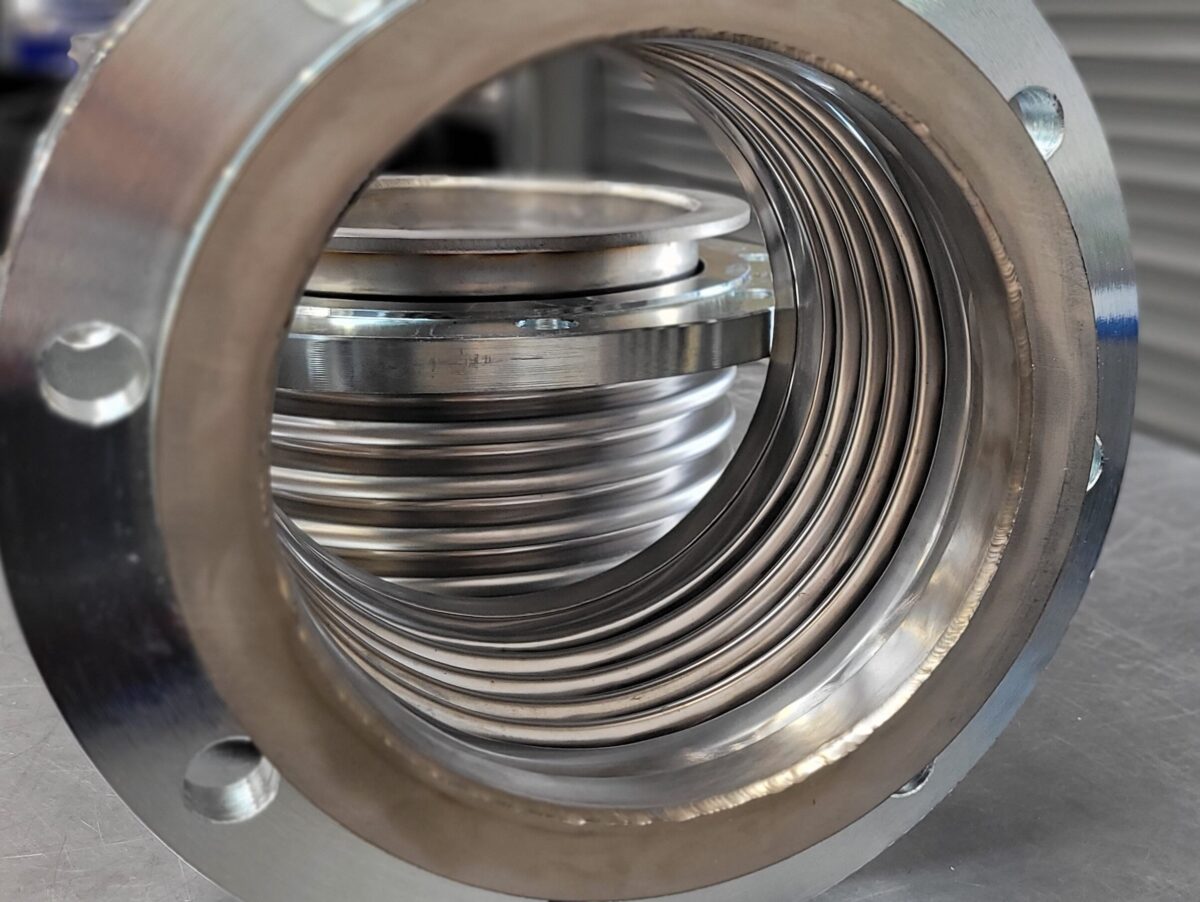

Understanding Metallic Bellows

Metallic bellows, also known as expansion joints, are flexible components crafted from metal alloys such as stainless steel, Inconel, or titanium. Their construction is typically single ply or multi-ply and involves a series of convolutions or corrugations that allow them to flex and bend while maintaining structural integrity. This design enables them to withstand high temperatures, pressures, and mechanical stresses encountered in industrial environments .They are supplied in various forms , single ply and multi ply are available as standard to accommodate axial movement , lateral movement and angular movement. their ability to compress , extend , bend and absorb various movements makes bellows ideal to be used in multiple ways .

![Expansion joint]()

Expansion joint ![Expansion joints]()

![Expansion joint]()

Adapting to Dynamic Environments

One of the primary functions of metallic bellows is to accommodate the thermal expansion and contraction of pipelines resulting from temperature variations. As temperatures fluctuate, pipelines expand and contract, exerting tremendous forces that can lead to structural damage if not properly managed. Metallic bellows act as flexible joints, absorbing these movements and preventing undue stress on the system.

Moreover, they excel in dampening vibrations generated by machinery, pumps, or turbulent fluid flow within pipelines. By absorbing and dissipating vibrations, bellows mitigate the risk of equipment damage and ensure smoother operation of industrial processes.

The versatility of metallic bellows extends across various industrial sectors, where they find application in an array of critical systems:

Versatility Across Industries

Actuators

Metallic bellows are utilized in actuators to convert fluid pressure or mechanical motion into linear or rotary motion, enabling precise control in valves, dampers, and other automated systems.

Expansion Joints

As the name suggests, expansion joints accommodate the expansion and contraction of pipelines due to temperature changes, preventing structural damage and maintaining system integrity.

Mechanical Seals

In pumps and rotating equipment, metallic bellows serve as sealing elements, preventing leakage of fluids or gases while allowing axial movement to compensate for shaft misalignment or thermal expansion.

Valve Seals

Bellows are employed in valve assemblies to provide a flexible barrier between the valve stem and the pressurized fluid, ensuring leak-tight sealing even under extreme conditions.

Thermal Expansion Tanks

These tanks incorporate metallic bellows to absorb the expansion of fluid or gas within a closed system, preventing over pressurisation and maintaining optimal operating conditions.

Reservoirs

In hydraulic systems, bellows are integrated into reservoirs to accommodate fluid level variations resulting from temperature changes or system operation.

Aerospace

Metallic bellows are used for fuel line , exhaust system and other applications that require flexibility and durability in extreme environments .

Petrochemical

Metallic bellows and expansion joints are used to compensate for movement and vibration in pipelines , reactors and other equipment .

H and V

Metallic bellows are widely used in the construction of large buildings they are used to accommodate the movement in pipework conveying hot and cold water .

Power generation

Metallic bellows are used in nuclear and gas power generating to compensate for thermal expansion and vibration in piping and equipment .

Automotive

Metallic bellows are widely used in the automotive industry on exhaust system to compensate for thermal expansion caused by changes in temperature.

Water industry

Metallic bellows are used in sewage treatment works where the sewage is aeriated by air using large diameter pipework , they accommodate the movement caused by thermal expansion.

Medical equipment

Metallic bellows are used in the medical equipment such as ventilators , anaesthesia machines and surgical robots to provide precise motion control.

Conclusion

Being able to meet the intricate demands of the industrial pipelines means metallic bellows stand out as an indispensable components, offering flexibility, durability, and adaptability to diverse operational challenges. Whether managing thermal expansion, dampening vibrations, compensating for misalignments, or accommodating fluid movement, these versatile devices play a crucial role in ensuring the smooth and reliable operation of critical systems across various industries. As industrial processes continue to evolve, the demand for solutions like metallic bellows will continue to grow, reinforcing their status as vital assets in the realm of pipeline engineering.

Industries

Get in touch

It’s time we talked, send a message

Speak to an experienced engineer to discuss your unique requirements